From 2025, Zero Energy Building (ZEB) standards will be mandatory for all new constructions, and related industries are preparing in full swing. Along with passive elements such as high insulation and airtightness, active systems like heating and cooling equipment are focusing on high-efficiency development.

In particular, ventilation systems for ZEBs must go beyond efficiency to address overlooked challenges in conventional buildings—such as latent heat removal and humidity control.

The Korea Institute of Science and Technology (KIST) has developed a Desiccant Dehumidification System that combines high heat recovery ventilation with superior dehumidification, offering a breakthrough solution for Passive House applications. We spoke with Dr. Dae-Young Lee, Head of KIST’s Urban Energy Research Center, about the unique ventilation challenges in Passive Houses and their solutions.

■ Characteristics of Passive House Ventilation

In summer, cooling loads come from external heat gains, internal equipment, human activity, and ventilation. In ordinary buildings, poor insulation and airtightness make external heat the largest factor.

Passive Houses, however, minimize external heat but see a relative increase in human-related latent heat and ventilation load. Since about half of this is latent heat (e.g., sweat, moisture), failure to manage it leads to higher humidity and discomfort—often worse than in standard housing.

Even in ordinary homes, this is familiar during monsoon season, where discomfort stems more from humidity than temperature. Using air conditioners for dehumidification cools the room too much, forcing residents to turn systems on and off, creating inefficiency and discomfort. In Passive Houses, this can be a constant issue, leading some early adopters to complain: “It’s too humid to live comfortably.”

Moreover, lowering AC settings for stronger dehumidification reduces efficiency by about 3% per 1°C, increasing power consumption.

■ The Developed ‘Desiccant Dehumidification System’

Until recently, efficiency certification standards for heat recovery ventilators were 45% for cooling and 70% for heating. Cooling efficiency is harder to achieve because latent heat transfer requires moisture transfer, which is more resistant than sensible heat exchange. Plate-type exchangers therefore have limits in latent heat recovery.

KIST’s Desiccant Dehumidification System adopts a rotary heat exchanger, achieving equal sensible and latent heat exchange. The technology—Low-Temperature Regeneration Solid Desiccant with Heat Recovery Ventilation—has earned the Ministry of Trade’s New Excellent Technology (NET) certification. It delivers 71.5% efficiency in cooling and 79.1% in heating, enabling precise temperature and humidity control.

This far exceeds the 45% cooling efficiency benchmark and demonstrates superior latent heat recovery, making it essential for the growing Passive and Zero Energy House market.

■ Outstanding Dehumidification Performance

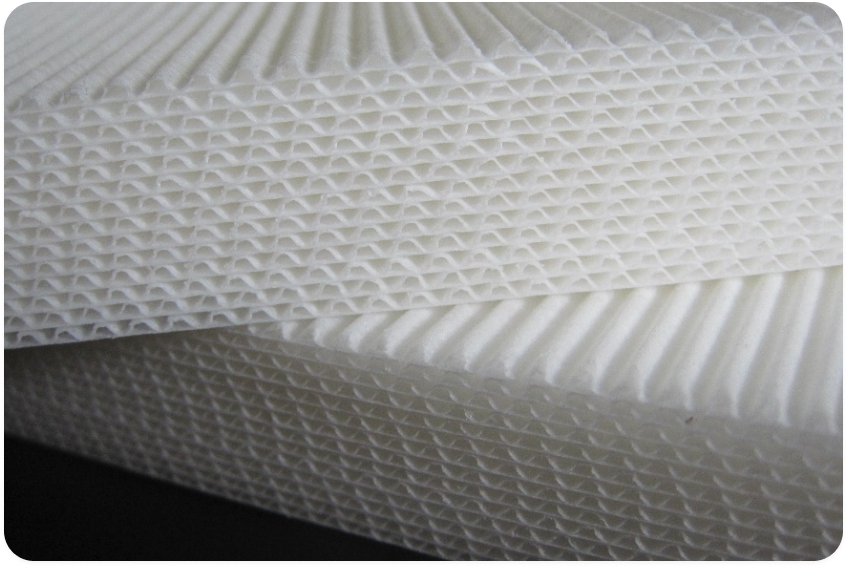

The system’s heat exchanger uses KIST’s proprietary polymer hygroscopic material, which is 4–5 times more effective than silica gel and among the world’s best in dehumidification. Tested over 100,000 absorption–desorption cycles, it also provides antibacterial, antifungal, and deodorization functions, while being safe and easy to process.

The material has earned Korean (2010) and U.S. (2011) patents, the 2014 KIPO Patent Technology Award, and 2017 Ministry of Environment Green Technology certification.

As a result, the system achieves a dehumidification efficiency of 2.89, far surpassing conventional electric dehumidifiers (1.6–2.0) and even the top Tier-1 efficiency standard of 1.78—delivering 162% of Tier-1 performance. Considering that the gap between Tier-1 and Tier-2 is just 10%, this marks a revolutionary advancement.

Its dual-stage design first condenses moisture like a traditional electric dehumidifier, then uses the polymer filter for secondary absorption. This ensures outlet air temperature remains the same as inlet air, avoids hot exhaust, and allows semi-permanent filter regeneration using internal warm air. As a result, energy use remains constant while dehumidification capacity doubles.

Same temperature, no humidity. Humicon features desiccant technology that helps maintain optimal humidity at 40%. It also includes air purification and ventilation functions, ensuring fresh and clean indoor air.

Huzero is an industrial dehumidifier designed for low-temperature and extremely low-humidity environments to improve factory productivity, offering energy efficiency 60% higher than existing market products.

Husheet is an innovative and patented technology, ultra-slim dehumidifier that can control humidity as well as deodorizing. It also has dehumidifying, deodorizing, antibacterial, and anti-fungal functions.

Protect your valuable clothes and belongings from humidity with Huspot, a desiccant dehumidifier designed specifically for dressing rooms in your home. Huspot effectively removes moisture from bathrooms and other areas using advanced desiccant technology, and safely release the humidity outside. Therefore, it is not neccessary to empty a water tank, install pipes, or worry about water leaks. Huspot can be installed on the ceiling, allowing you to maximize the use of your dressing room space while maintaining an optimal humidity level for your clothes and accessories. Keep your dressing room fresh and humidity-free with Huspot.